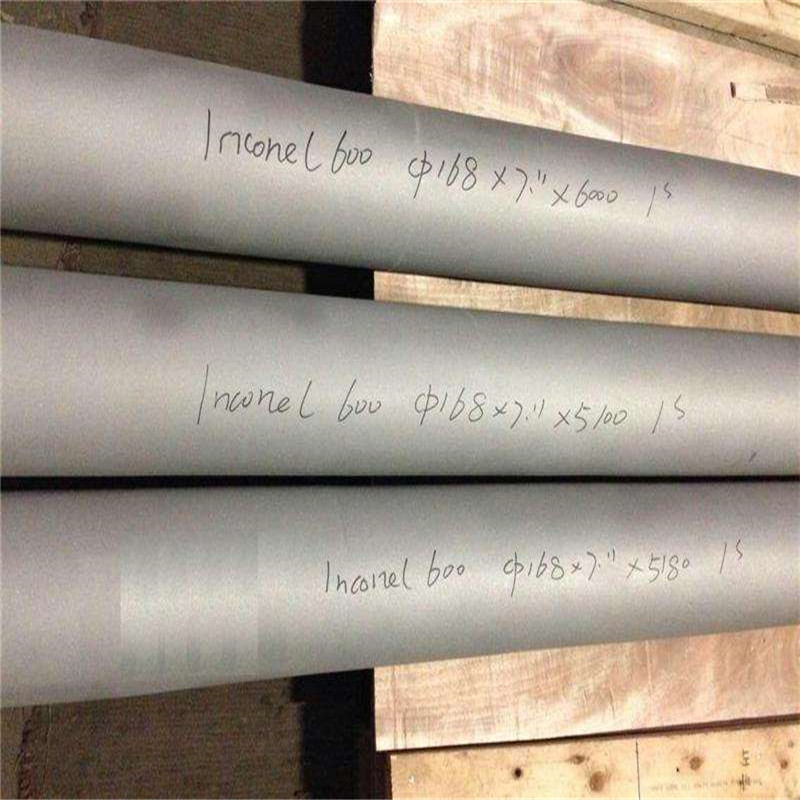

Inconel consists of a specific group of nickel alloys or nickel-chromium alloys. Inconel is durable, corrosion-resistant, rust-proof and very strong. These alloys are manufactured in different grades and come in different sizes and shapes.

Why does the aerospace industry use Inconel?

Inconel plays a vital role in the aerospace industry. Inconel is a variety of nickel-based alloys widely used in aerospace engineering. These nickel alloys used in aerospace are selected for their strength against high temperatures, corrosion and sustained wear, as well as their magnetic properties. Nickel alloys are structurally one of the hardest materials and are good conductors of electricity.

Inconel grades have a variety of uses in aerospace components, including gas turbine rotors, blades and seals, afterburner components, flame stabilizers, heat exchangers, heat treatments, heat shields, instrument components, Combustion tanks, aerospace liners, transition ducts, pipes, valves, pipes and bolts.

Structural applications requiring specific corrosion resistance or high temperature strength can obtain the necessary properties of nickel and its alloys. Oxidation, corrosion and high stress resistance of nickel alloys at high temperatures (1200°F-2000°F, 650°C-1100°C). This property makes the metal particularly suitable for manufacturing jet engine parts and their components. Therefore, Inconel is often used in the manufacture of aircraft components, such as aircraft engines, exhaust devices, heat exchangers, APU components, air bleed ducts, etc., most of which involve corrosion resistance and heat resistance.

What are the basic properties of Inconel?

Inconel plays an important role in protecting other components when encountering high-pressure environments and situations. These alloys are used in aircraft components that require a high degree of safety at high pressures, such as heat shields, gas turbine blades and engine exhaust ducts.

Resistance to high temperatures and the ability to maintain itself over a wide temperature range are two properties of Inconel that are highly sought after in the aerospace industry. Aircraft parts that must operate in high-temperature environments for many years are well suited for Inconel. Inconel will benefit greatly when it is integrated into aircraft jet engines and engine exhaust systems.

Inconel has hardening properties that make it more suitable for high temperature situations than steel and aluminum materials. Metal alloys are new solutions to long-standing industrial problems, such as the need for heat-resistant parts and materials. The material offers high strength and corrosion resistance and can be used in extreme temperatures from -252°C to 704°C. It forms a thick and stable passivating oxide layer at high temperatures to protect the material from further attack.

What are the advantages of Inconel in the aerospace field?

Inconel has significant advantages in the aerospace field. They are vital to the aerospace industry. Without the use of these versatile metals, aircraft would struggle to find alternative alloys to provide them with the same functions necessary for high efficiency and reliability. Inconel has many advantages, including tremendous strength at high temperatures, excellent resistance to oxidation and corrosion. In addition, it exhibits low expansion at severe temperatures and is creep-resistant under high pressure conditions, making it useful for labyrinth seals and fireproof sealing of exhaust devices.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Dec-27-2023