Nilo alloy 42 is an iron-nickel-cobalt-based high-temperature alloy that has become increasingly popular over the past few years. It is known for its excellent creep properties, oxidation resistance and high temperature resistance. This makes it ideal for use in a variety of applications such as the aerospace, petrochemical and nuclear industries. This article will discuss the composition, mechanical properties, physical properties and uses of Nilo Alloy 42.

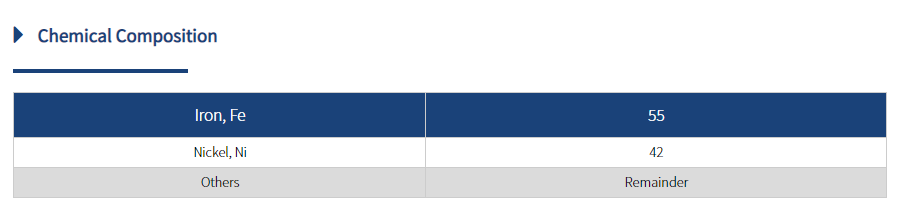

Alloy 42 Chemical Composition:

UNS K94100 contains approximately 22% nickel and 13% cobalt, with small amounts of chromium (0.12%), molybdenum (0.30%), tungsten (0.50%), silicon (0.15%), manganese (0.20%), and aluminum (0.30 %) ). This combination of elements makes it an excellent choice for applications requiring high temperatures or extreme conditions due to its high strength-to-weight ratio and superior corrosion resistance compared to other alloys in the series.

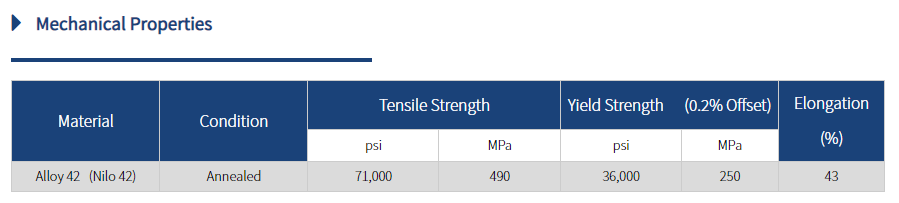

Nilo Alloy 42 Mechanical Properties:

Nilo Alloy 42 has a tensile strength of 140 ksi (960 MPa) and a yield strength of 90 ksi (620 MPa) at room temperature. In addition to its strength properties, it has good ductility, with an elongation of greater than 25%. It also maintains strength at temperatures up to 1100°F (593°C).

Specification:

▪ UNS: K94100

▪ Werkstoff Nr. 1.3917

▪ ASTM F29 Wire

▪ ASTM F30 Sheet, Strip, Rod, Bar, Tubing, Wire

▪ B753 Sheet and Strip

▪ SEW 385 Sheet, Strip, Bar

▪ DIN 17745

▪ AFNOR NF A54-301

▪ Nilo 42

Nilo Alloy 42 applications:

Nilo alloy 42 is used in many industrial applications due to its unique properties, including corrosion resistance, heat resistance and high tensile strength. Some common applications include gas turbine blades, aircraft exhaust systems, and nuclear power plant components such as piping systems or fasteners; petrochemical components such as valves or pumps; medical implants; and aerospace components such as bearings or wheel hubs.

in conclusion:

In summary, Nilo Alloy 42 is an iron-nickel-cobalt-based superalloy with excellent creep and oxidation resistance compared to other alloys in its class. Due to its excellent mechanical properties, such as high tensile strength and ductility, it is used in a variety of industries, even at high temperatures up to 1100°F (593°C). It also has good corrosion resistance, making it ideal for applications such as gas turbine blades, aircraft exhaust systems, nuclear power plant components, petrochemical components, medical implants and aerospace components.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Feb-21-2024