If you are looking for a high-performance alloy that can withstand extreme temperatures, pressures and corrosive environments, MP35N may be the perfect choice for your needs. This advanced nickel-based alloy has a unique combination of mechanical and physical properties, making it ideal for a variety of industrial applications, from aerospace and gas turbines to chemical processing and oil drilling. So, what makes the MP35N so unique? In this article, we’ll take a deep dive into the MP35N’s ingredients, features, and uses to help you understand how it works and why it’s important.

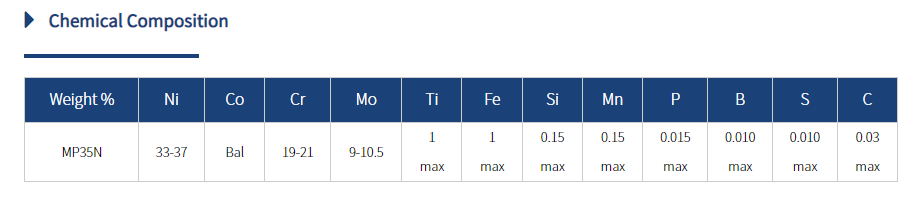

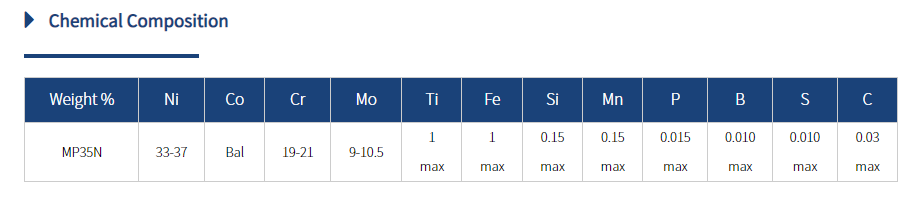

MP35N chemical composition:

MP35N is a nickel-cobalt-chromium superalloy containing 39% nickel, 20% cobalt, 19% chromium, 9.5% molybdenum and other elements such as titanium, aluminum and tungsten. The alloy is designed to provide high strength, toughness and resistance to thermal fatigue, creep and corrosion. The unique composition of MP35N makes it highly resistant to oxidation, sulfurization and other forms of environmental attack, even at temperatures in excess of 982°C (1800°F).

MP35N mechanical properties:

MP35N exhibits excellent mechanical properties, including high tensile strength (up to 1250 MPa), yield strength (up to 870 MPa) and elongation (up to 25%). The alloy also has good hardness (up to 38 HRC), fatigue strength and fracture toughness, making it suitable for demanding applications such as jet engine components, land-based gas turbines and nuclear reactors. In addition, MP35N has good weldability and machinability, simplifying the manufacturing and assembly process.

Standard:

▪ UNS R30035

▪ AMS 5758 – MP35N® VIM-VAR Bar

▪ Solution heat treated @1900-1925°F for 4 to 8 hours

▪ AMS 5844 – MP35N® VIM-VAR Bar

▪ Solution heat treated @1900-1925°F for 4 to 8 hours and Work Strengthened

▪ AMS 5845 – MP35N® VIM-VAR Bar

▪ Solution heat treated @ 1900-1925°F for 4 to 8 hours, Work Strengthened & Aged @ 1000-1200°F for 4 hours

▪ NACE MR0175

▪ ASTM F-562 – Surgical Implant Applications

▪ BS 7252-6 Surgical Implant Applications

▪ ISO 5832-6 Surgical Implant Applications

MP35N uses:

MP35N has a wide range of industrial applications requiring high temperature and corrosion resistance. Some typical uses include:

Aerospace and Defense: Engine components, airframe structures, exhaust systems, landing gear, fuel nozzles and heat exchangers.

Gas and steam turbines: turbine blades, rotors, discs and casings.

Chemical processing: reactors, heat exchangers, valves and piping systems.

Oil and Gas: Drilling equipment, wellhead components, valves and pipes.

Nuclear energy: fuel cladding, control rods and reactor internals.

MP35N corrosion resistance:

One of the most impressive properties of MP35N is its exceptional resistance to all forms of corrosion, including oxidation, sulfidation, nitriding and carburization. This is due to the high concentration of nickel and chromium in the alloy, which forms a protective oxide layer that prevents further corrosion. In addition, MP35N has good resistance to aqueous and non-aqueous environments such as acids, bases and salts. This makes it a popular choice for applications requiring resistance to corrosive gases and liquids.

MP35N welding:

Another key aspect of the MP35N is its weldability, allowing multiple parts or components to be easily connected. However, the welding of MP35N requires careful attention to the welding process and the selection of appropriate filler materials. For example, gas tungsten arc welding (GTAW) is preferred for welding this alloy due to its low heat input and precise weld pool control. Likewise, it is recommended to use a nickel-based filler metal such as alloy 625 or alloy 686 to join MP35N as it matches the chemical composition and mechanical properties of the base material.

in conclusion:

In summary, MP35N is a unique and valuable superalloy with exceptional strength, toughness and corrosion resistance under extreme conditions. Its composition, mechanical and physical properties, and welding characteristics make it an attractive option for various industries requiring high-performance materials. By understanding the features and applications of the MP35N, you can make an informed decision about whether it is suitable for your specific needs. Choosing the right alloy can make a huge difference in the performance, reliability and durability of your equipment or product.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Feb-21-2024