In the field of engineering, the discovery and development of various materials that can be used in different industries has revolutionized the way work is done. Specifically, other alloys pave the way for innovations that further improve the way we live. MP159 is one such alloy. This blog will explore the composition, mechanical and physical properties of MP159 and its various uses in different industries. Let’s dive in!

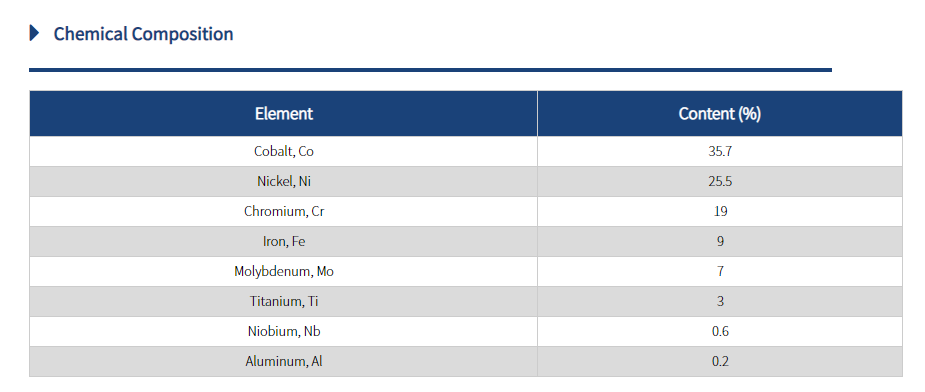

MP159 chemical composition:

MP159 is a nickel alloy containing small amounts of iron, aluminum and titanium. Its nickel content is 25.5%. The small amounts of iron, aluminum and titanium present in the alloy contribute to its strength, hardness and workability.

MP159 uses:

MP159 has a wide range of uses in various industries. It is commonly used in aerospace components where high strength, hardness and fatigue resistance are required, such as gas turbines. It is also used in the nuclear industry due to its excellent heat and corrosion resistance. Additionally, this alloy is commonly used in the chemical and petrochemical industries due to its resistance to corrosion and high temperature environments.

MP159 corrosion resistance:

MP159 is highly resistant to corrosion, making it an ideal material for use in harsh environments. It can withstand oxidizing and reducing environments as well as acidic and alkaline solutions. Its resistance to corrosion and high temperature environments makes it ideal for the chemical and petrochemical industries.

MP159 heat treatment:

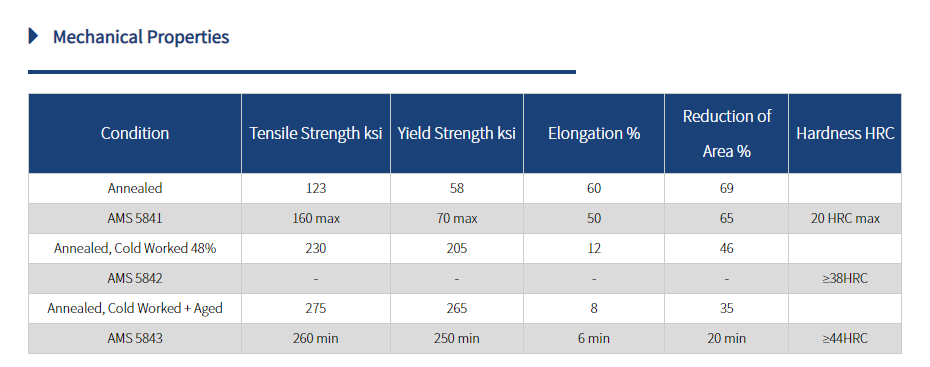

MP159 can be heat treated to enhance its mechanical properties. The heat treatment process involves annealing the alloy at 1900°F (1038°C) for four hours and then cooling at a rate of 200°F (111°C) per hour until the temperature reaches 1200°F (648°C). This process helps increase the strength and hardness of the alloy.

MP159 processing:

MP159 has good machinability but is challenging due to its high strength and hardness. In order to machine this alloy correctly, special tools and techniques are required. The use of coolant is also recommended to prevent overheating, which can cause the alloy to deform.

MP159 welding:

The MP159 can be welded using a variety of techniques such as Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW) and Stick Arc Welding (SMAW). However, due to its higher nickel content, proper precautions must be taken to prevent cracking. Preheating the alloy and maintaining the interpass temperature during welding helps prevent cracking.

in conclusion:

MP159 is a versatile alloy with a wide range of uses in different industries. Its exceptional strength, hardness, and resistance to high temperature environments and corrosion make it an ideal material for a variety of applications. This alloy can be customized to meet different engineering needs with appropriate heat treatment, machining and welding techniques. Discovering the wonders of the MP159 is just the beginning of the endless possibilities.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Feb-22-2024