In engineering, it is crucial to use materials that are resistant to high temperatures and corrosion. One such material is Hastelloy X-750, a nickel-based alloy with excellent mechanical and physical properties. This blog takes an in-depth look at Hastelloy X-750’s ingredients, properties, uses, and more. So, read on to learn everything you need to know about the Hastelloy X-750.

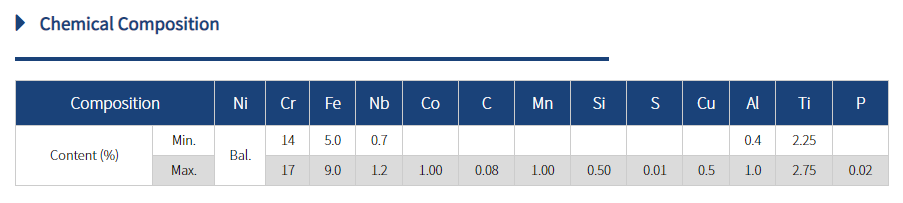

Hastelloy X-750 Chemical Composition:

Hastelloy X-750 is a nickel-chromium alloy with added aluminum, titanium and niobium. These elements give the alloy excellent high-temperature strength, corrosion resistance and oxidation resistance. The composition of Hastelloy X-750 makes it ideal for use in gas turbine engines, nuclear reactors, chemical processing plants and other high temperature applications.

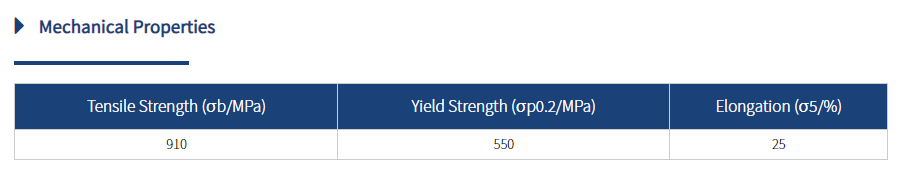

Hastelloy X-750 Mechanical Properties:

Hastelloy X - Unremarkable mechanical properties make it a popular choice for high temperature applications. It has a tensile strength of 220 ksi (1517 MPa) and a yield strength of 135 ksi (930 MPa). It also has excellent fatigue resistance, making it ideal for gas turbine engines subjected to frequent and repeated load cycles.

Hastelloy X-750 uses:

Hastelloy X-750 is commonly used in aerospace, chemical processing and nuclear power generation. In the aerospace industry, it is used in turbine blades, afterburner components and combustion chambers. In the chemical industry it is used in heat exchangers, reaction vessels and other high temperature applications. In the nuclear industry, it is used in reactor core components, steam generators and other critical components.

Hastelloy X-750 Corrosion Resistance:

Hastelloy X-750 offers excellent corrosion resistance, making it ideal for harsh environments. It resists corrosion from a variety of chemicals, including sulfuric acid, hydrochloric acid and sodium chloride. It also resists oxidation at high temperatures, which is critical in applications where the alloy is exposed to air.

Hastelloy X-750 Heat Treatment:

Hastelloy X-750 can be heat treated to improve its mechanical properties. Heat treatment involves heating the alloy to a specific temperature, holding it at that temperature for a period of time, and then cooling it back to room temperature. Heat treatment can improve the strength, ductility and fatigue resistance of the alloy.

Hastelloy X-750 Processing:

Hastelloy X-750 is a challenging material to machine due to its high strength and hardness. However, it can be machined using carbide tools, and the use of coolant is highly recommended. The right machining techniques and cutting tools help produce high-quality parts with the Hastelloy X-750.

Hastelloy X-750 Welding:

Hastelloy X-750 can be welded using a variety of methods, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW) and resistance welding. Due to the high strength and hardness of Hastelloy X-750, specialized welding techniques are required. Welding parameters such as heat input, preheating temperature and post-weld heat treatment should be carefully controlled to ensure a strong and reliable weld.

in conclusion:

Hastelloy X-750 is an excellent material for high temperature applications requiring strength, corrosion and oxidation resistance. Its composition, mechanical and physical properties, uses, corrosion resistance, heat treatment, machining and welding techniques make it a popular choice across multiple industries. Understanding the properties and applications of Hastelloy X-750 is critical for engineers designing and developing components and systems that require reliable and durable materials.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Jan-18-2024