Welding uses heat, pressure, or both to fuse two or more metals. It is vital in the construction, automotive and aerospace industries. However, welding requires proper equipment and materials to ensure a safe and long-lasting bond. One of the most popular welding wires available today is HAYNES® 263/C-263 welding wire, known for its superior performance and versatility. This article will provide an in-depth look at the composition, mechanical and physical properties, corrosion resistance, heat treatment and uses of HAYNES® 263/C-263 welding wire.

What is HAYNES® 263/C-263 Welding Wire?

HAYNES® 263/C-263 Welding Wire is a nickel-based alloy used for welding in high temperature applications up to 2000°F. It can join many dissimilar metals and has excellent creep strength, oxidation resistance and corrosion resistance. The wire welds well in both as-welded and aged conditions, making it ideal for joining nuclear fuel rod cladding components or other components exposed to high temperatures. It is also popular in exhaust valve stems due to its good fatigue strength properties.

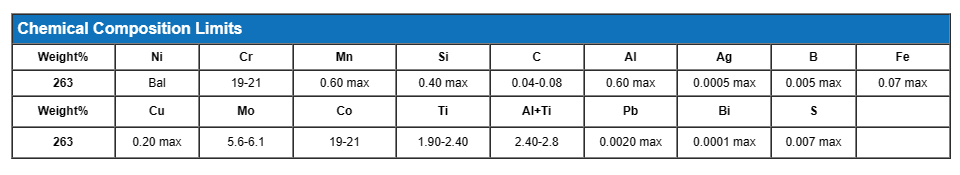

HAYNES® 263/C-263 Coated Wire Chemical Composition:

HAYNES® 263/C-263 welding wire is made from a variety of metals and alloys, containing 20-22% chromium, 19-21% nickel, 5-6% molybdenum, 0.4-1.2% titanium and trace amounts of boron, carbon, cobalt, Copper, iron, manganese, phosphorus, silicon and sulfur. These ingredients are blended together to form a welding wire with excellent corrosion and heat resistance.

AYNES® 263/C-263 welding wire mechanical properties:

HAYNES® 263/C-263 electrode has excellent mechanical properties, including high yield strength (625 MPa), ultimate tensile strength (1055 MPa) and elongation (40%). This means that the welding wire can withstand significant stresses and pressures, making it suitable for high temperature and high stress applications.

HAYNES® 263/C-263 Coated Wire Physical Properties:

In addition to mechanical properties, HAYNES® 263/C-263 electrode has impressive physical properties such as a density of 8.19 g/cm3, a melting point of 1350-1450°C, and a thermal expansion coefficient of 13.3 microns/meter°C. These physical properties make it ideal for extreme temperatures where other welding wires may not be usable.

HAYNES® 263/C-263 Welding Wire Corrosion Resistance:

One of the most significant advantages of HAYNES® 263/C-263 filler metal is its corrosion resistance. The wire can withstand corrosive environments such as seawater, sulfuric acid, acetic acid and nitric acid, making it ideal for marine, chemical and petrochemical applications. Additionally, its resistance to all forms of corrosion means it is extremely durable and requires minimal maintenance.

HAYNES® 263/C-263 coated wire heat treatment:

HAYNES® 263/C-263 wire can also be heat treated to further enhance its performance. Preheating the wire before use reduces the likelihood of cracking, and annealing improves its machinability and toughness. Welding wire can also be used for welding and brazing using standard procedures, including TIG and MIG welding, gas shielded welding, and gas shielded arc welding.

HAYNES® 263/C-263 coating line uses:

HAYNES® 263/C-263 filler wire is a superalloy designed for high performance welding applications, especially in corrosive environments. The alloy’s high strength and fatigue resistance make it ideal for use in many industries, including aerospace, oil and gas exploration and production equipment, chemical processing components, marine propulsion systems and medical implants. It is commonly used to weld pressure vessels, piping systems or other structures exposed to crevice corrosion or erosion.

in conclusion:

In summary, HAYNES® 263/C-263 welding wire is an excellent welding wire with many advantages. Its composition, mechanical and physical properties, corrosion resistance and heat treatment capabilities ensure that it can withstand harsh conditions and perform optimally in a variety of applications. Whether in the construction, automotive or aerospace industries, HAYNES® 263/C-263 welding wire is the perfect welding wire for your needs.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Jan-23-2024