Hastelloy X, also known as HX, is a nickel-based alloy known for its exceptional strength and heat resistance. As a superalloy, Hastelloy X is widely used in applications that require reliable performance in extreme environments such as high temperatures and corrosive conditions.

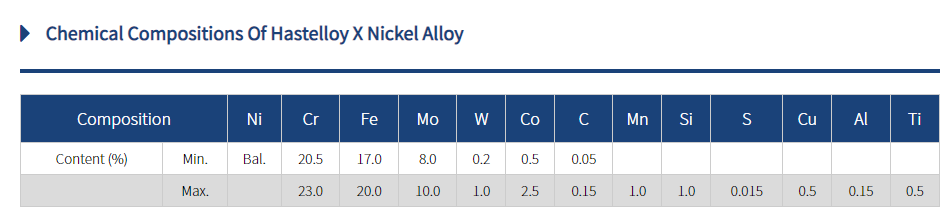

Hastelloy X Chemical Composition:

Hastelloy X contains varying amounts of nickel, molybdenum, chromium and iron. Additionally, the alloy contains small amounts of tungsten, cobalt and carbon. The chemical composition gives the alloy excellent corrosion resistance and mechanical strength.

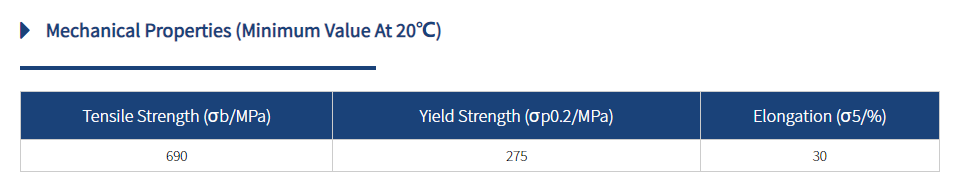

Hastelloy X Mechanical Properties:

Hastelloy X offers high strength due to its optimal combination of nickel, molybdenum and chromium content. It is known for its ability to withstand temperatures in excess of 1000°F while maintaining strength. It has excellent mechanical properties such as excellent tensile and yield strength, good ductility and toughness.

Hastelloy X Physical Properties:

Hastelloy X has high thermal conductivity and low coefficient of thermal expansion. It has a specific gravity of 8.22 g/cm3 and a melting point of 2,381°C (4,318 °F). It also has excellent resistance to thermal fatigue.

Hastelloy X Corrosion Resistance:

Hastelloy X has excellent corrosion resistance against various corrosive media such as sulfuric acid, hydrochloric acid, and nitric acid. It is also resistant to oxidizing media such as seawater and most organic acids. These properties make it ideal for harsh environments with a high risk of corrosion.

Hastelloy X Heat Treatment:

Hastelloy X can be heat treated to enhance its strength and toughness. The alloy can be easily annealed by heating to 2150°F and then air cooling. It can also be tempered to increase its toughness by heating it to 1900°F and then air cooling.

Hastelloy X Processing:

Hastelloy X has excellent machinability compared to other nickel-based superalloys. But due to its high strength, the machining process should be done using appropriate tools and techniques to avoid tool wear and breakage. The use of coolant is also recommended to prevent overheating, which can cause work hardening or cracking.

Hastelloy X Welding:

Hastelloy X can be welded by a variety of welding methods, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW) and submerged arc welding (SAW). GTAW is favored for its high-quality welds and lower heat input, which reduces the likelihood of cracking.

in conclusion:

In summary, Hastelloy X is an excellent nickel-based superalloy known for its strength, heat resistance, and corrosion resistance. Its superior performance makes it ideal for a variety of industrial applications, including aerospace, gas turbines, furnace hardware and petrochemical processing equipment. The heat treating, machining and welding capabilities of Hastelloy X give it a wider range of applications in different industries. However, selecting Hastelloy X requires understanding its properties and careful consideration of its application requirements.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Dec-29-2023