What is Inconel 686?

Inconel 686 is a Ni-Cr-Mo superalloy with excellent corrosion resistance, high temperature strength and outstanding toughness. It has excellent thermal fatigue strength and can be used in parts that withstand cyclic heating and cooling in harsh environments.

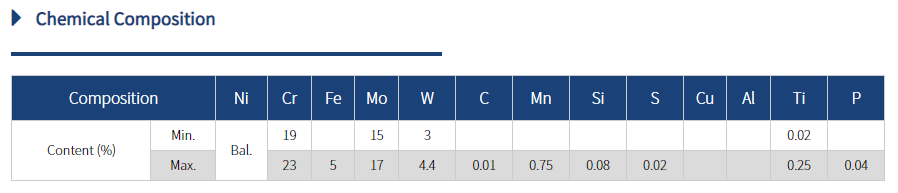

Inconel 686 Chemical Composition:

Inconel 686 is a nickel-based superalloy containing chromium, molybdenum, tungsten and iron as additional elements. Its chemical composition resists a variety of corrosive media, including acids, salts and seawater. Additionally, Inconel 686 offers excellent high-temperature strength, toughness and durability. The alloy is heat treatable and can be hardened by controlled heating and cooling.

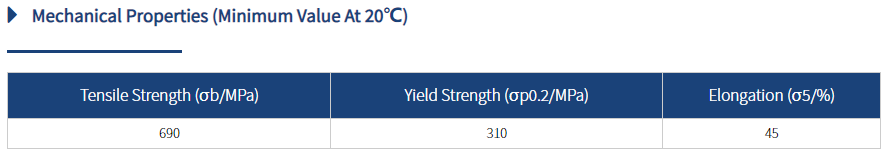

Inconel 686 mechanical properties:

Regarding mechanical properties, Inconel 686 has a tensile strength of 100-130 ksi and a yield strength of 55-75 ksi. It also has excellent fatigue resistance, impact strength and creep resistance. Moreover, it maintains its performance under high temperature and pressure environments, making it the material of choice for oil and gas extraction and processing.

The unique properties of Inconel 686 make it a versatile material in many fields. Due to its resistance to highly corrosive chemicals, it is used in chemical processing such as reactors, vessels and piping. It is also used in the aerospace industry for engine components, afterburner components and heat exchangers. In addition, the alloy is used in the marine industry for seawater intake valves, pump casings and propeller shafts.

Inconel 686 corrosion resistance:

Inconel 686 is highly resistant to corrosion caused by a variety of environments. It has excellent resistance to pitting corrosion, stress corrosion cracking and intergranular corrosion. Corrosion resistance is enhanced by the addition of tungsten and molybdenum, promoting the formation of a stable and passivating oxide layer on the alloy surface.

Inconel 686 heat treatment:

Inconel 686 requires heat treatment to achieve its best performance. Heat treatment involves heating a material to a high temperature, holding it at that temperature for a specific period of time, and then cooling it in a controlled manner. The process can change the microstructure of the alloy, improving its strength, toughness and other properties. Thermal treatment is critical to achieving the desired performance based on the intended application.

Inconel 686 processing:

Finally, Inconel 686 is an ideal material for machining due to its excellent formability and ductility. The alloy can be machined using standard techniques including milling, drilling, turning and grinding. However, due to its high strength and toughness, special cutting tools and methods may be required.

Inconel 686 welding:

Welding of Inconel 686 may require some precautions to prevent cracking and ensure optimal performance.

in conclusion:

Inconel 686 is a high-performance nickel-based alloy with excellent corrosion resistance, high temperature resistance, and pressure resistance. The alloy facilitates a variety of applications including chemical processing, aerospace and marine industries. Its composition, mechanical and physical properties make it suitable for use in the most demanding environments. With proper heat treatment and machining, Inconel 686 can be customized to meet specific application requirements. Although welding is somewhat difficult, expert attention can ensure the best performance of this alloy. Inconel 686 remains one of the most popular materials due to its unique properties, performance and reliability.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Mar-06-2024