Hastelloy S is a nickel-based alloy known for its exceptional strength and resistance to all forms of corrosion. It was created to address the limitations of its predecessor, Hastelloy C, and has become a popular material across multiple industries. This article will take an in-depth look at Hastelloy S and cover its composition, mechanical and physical properties, uses, corrosion resistance, heat treatment, machining and welding.

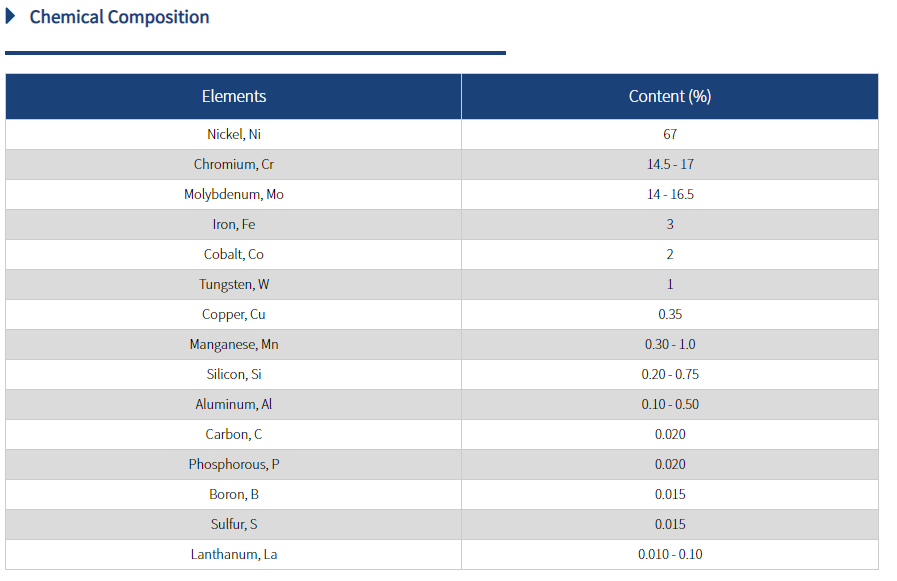

Hastelloy S Chemical Composition:

Hastelloy S consists primarily of nickel, chromium and molybdenum. Its chemical composition also includes tungsten, silicon, carbon, manganese and iron. The specific amounts of each element vary depending on the grade and use of the alloy.

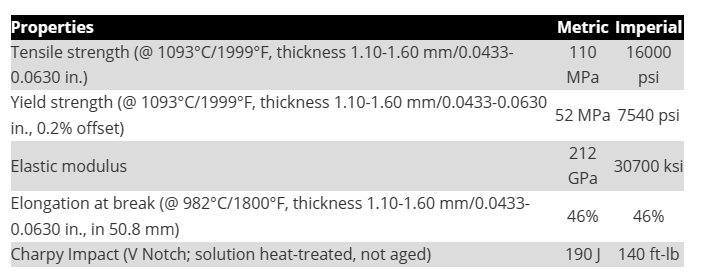

Hastelloy S Mechanical properties:

Hastelloy S has excellent mechanical properties including high strength, toughness and ductility. Its minimum yield strength is 330 MPa and its minimum tensile strength is 760 MPa. It can also withstand high temperatures and is suitable for extreme environments.

Hastelloy S Standard

AMS 5711

AMS 5838

AMS 5873

Hastelloy S uses:

Hastelloy S is used in a variety of applications including chemical processing, aerospace, nuclear power and the marine industry. Its high strength and corrosion resistance make it ideal for components and equipment exposed to aggressive and corrosive media.

Hastelloy S Corrosion Resistance:

Hastelloy S is highly resistant to a variety of corrosive environments, including sulfuric, hydrochloric, phosphoric and organic acids. It is also resistant to corrosive gases such as hydrogen sulfide, chlorine and chlorine dioxide.

Hastelloy S Heat Treatment:

Hastelloy S can be heat treated to increase strength and toughness. The recommended heat treatment is solution annealing at 1175°C for one hour followed by air cooling. The process enhances the alloy’s corrosion resistance while maintaining its mechanical properties.

Hastelloy S Processing:

Hastelloy S is challenging due to its high strength and toughness. It is recommended that carbide tools be used and machining should be done at slow speeds to avoid work hardening. Coolant must also be used to prevent overheating and reduce tool wear.

Hastelloy S welding:

Hastelloy S can be welded using a variety of welding processes, including TIG, MIG and SMAW. However, carefully following recommended welding procedures is crucial to avoid cracks and other problems. The alloy should also be preheated before welding to minimize thermal stress.

in conclusion:

Hastelloy S is an excellent material for applications requiring high strength, toughness and corrosion resistance. Its mechanical and physical properties and resistance to aggressive environments make it a popular choice across industries. Machining and welding this alloy can be challenging, but carefully following recommended procedures is critical to avoiding problems. If you’re considering using Hastelloy S for your next project, talk to an expert to ensure you’re getting the most out of this remarkable material.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Jan-18-2024