Inconel® 718 Welding Wire is a high-temperature nickel alloy widely used in aircraft and gas turbine engine components. It has excellent corrosion resistance and high strength at high temperatures. This blog will discuss the composition, mechanical and physical properties, uses, corrosion resistance and heat treatment of Inconel® 718 welding wire.

WHAT IS Inconel® 718 WELDING WIRE?

Inconel® 718 Welding Wire is a high performance alloy designed to resist high temperature corrosion. It has good weldability and can connect dissimilar nickel steel, stainless steel and other alloys. This wire has excellent resistance to thermal cycle fatigue and oxidation at temperatures up to 2000°F (1095°C). The alloy also combines high strength with exceptional flexibility and long service life in the most extreme environments.

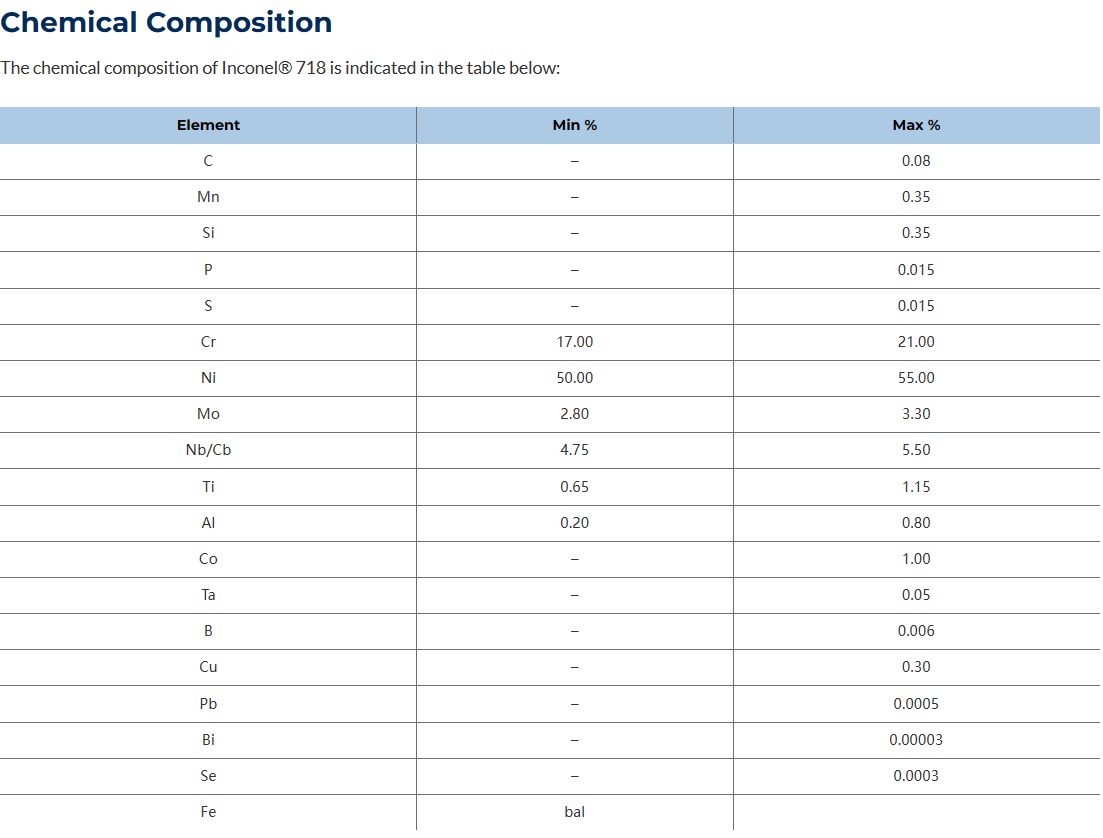

Inconel® 718 welding wire composition:

Inconel® 718 welding wire is a nickel-chromium alloy containing significant amounts of iron, niobium and molybdenum. It also contains trace amounts of titanium, aluminum and cobalt. The combination of these elements gives Inconel® 718 welding wire its unique properties.

Inconel® 718 welding wire uses:

Inconel® 718 welding wire is a versatile material used in a variety of applications including aircraft and gas turbine engine components, nuclear applications and chemical processing equipment. It has excellent corrosion resistance and is suitable for harsh environments. It is also widely used in the aerospace industry to manufacture parts requiring high strength and durability.

Inconel® 718 Welding Wire Corrosion Resistance:

Inconel® 718 welding wire is known for its excellent corrosion resistance. It resists corrosion in harsh environments, including acidic and alkaline solutions and high-temperature gases. Its ability to resist stress corrosion cracking makes it an ideal material for nuclear applications.

Inconel® 718 Welding Wire Heat Treatment:

Inconel® 718 wire can be heat treated to increase strength and toughness. Heat treatment involves heating materials to high temperatures and then rapidly cooling them. The process increases the material’s yield and tensile strength and improves its durability.

in conclusion:

Inconel® 718 welding wire is a nickel-chromium alloy known for its high strength and excellent corrosion resistance. Its unique composition and mechanical and physical properties make it ideal for high stress and high temperature applications. Its versatility and durability make it a popular choice in the aerospace, nuclear energy and chemical processing industries. If you are looking for a material that can withstand harsh environments and maintain strength at high temperatures, Inconel® 718 welding wire is an excellent choice.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Jan-23-2024