Incoloy 803 is an austenitic stainless steel alloy with excellent corrosion resistance and high temperature capabilities. It is resistant to oxidation, stress corrosion cracking and pitting corrosion. Incoloy 803 is a cost-effective material used in a variety of applications ranging from food processing to aerospace engineering. This blog post will explore the composition, properties, uses, and machinability of this popular alloy.

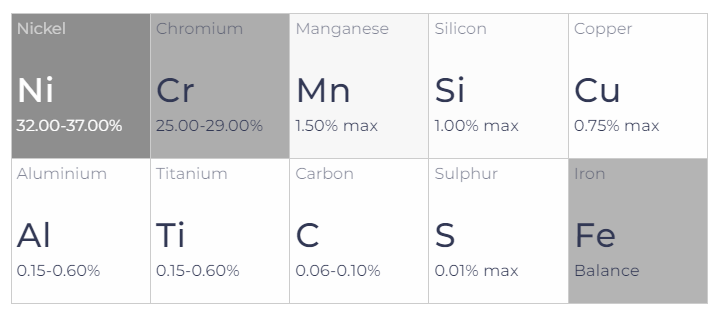

Incoloy 803 chemical composition:

Incoloy 803 is composed of 24-26% chromium, 19-22% nickel, 1-2% manganese, 0.5% titanium and up to 70% iron. It also contains up to 0.04% carbon and 0.35% sulfur as well as trace amounts of other elements such as molybdenum and silicon. This composition makes it resistant to corrosion in many environments, including seawater, acids and chloride solutions.

Incoloy 803 Properties:

Incoloy 803 is a nickel-iron-chromium alloy with impressive chemical properties, such as excellent corrosion resistance and formability. The alloy features low carbon, silicon and aluminum content, allowing it to increase tensile strength under both hot and cold working conditions. Incoloy 803 is also resistant to crevice corrosion and pitting corrosion, making it ideal for use in many high temperature environments. It can be used in equipment components subjected to severely corrosive atmospheres, such as those found in sulfuric or phosphoric acid processing. With its unique physical, mechanical and thermal properties, it’s no surprise that Incoloy 803 is favored in many industrial applications.

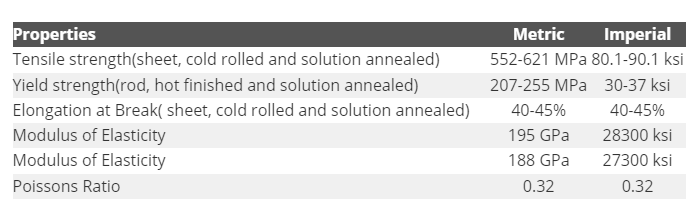

Incoloy 803 mechanical properties:

Incoloy 803 is an alloy widely used due to its excellent mechanical properties. The alloy offers excellent corrosion resistance, outstanding strength and high toughness. It also has excellent working characteristics in hot and cold conditions. Its ability to maintain stable and consistent mechanical properties over a wide range of temperatures makes it highly sought after in many industries, including power generation, industrial furnaces and chemical processing. Its unique properties make Incoloy 803 the right choice for applications requiring superior mechanical properties, even in harsh environments.

Incoloy 803 uses

Due to its excellent mechanical properties at high temperatures, Incoloy 803 is used in heated components such as pressure vessels in refineries or power plants, nuclear reactors and heat exchangers. Because of its excellent resistance to oxidation at temperatures up to 1800°F (980°C), it is also used in furnace components that require good creep resistance at high temperatures. Additionally, it can be used for fasteners due to its superior processability when machined or welded compared to other alloys such as 316L stainless steel or Inconel 600/601/625 alloys. Other uses include valves because of its good corrosion resistance in acidic media; exhaust manifolds because of its excellent heat resistance; pump shafts because they do not wear out quickly; turbine blades because they are strong and lightweight; chemical Processing equipment because they can withstand the wear caused by corrosive media; Food processing equipment because of their non-magnetic properties; Aircraft parts because of their low thermal expansion; Nuclear fuel rods because of their radiation resistance; Petrochemical plant components because they are resistant to sulfides Stress cracking; medical implants, because they are biocompatible; wires, because their conductivity values are higher than most other similar materials; automotive parts, because they have good fatigue strength at high temperatures, and finally, furnace parts Excellent oxidation resistance at high temperatures without embrittlement due to rapid cooling cycles like Incoloy 800H/HT is required.

Heat resistance:

Incoloy 803 is an iron, nickel and chromium alloy with excellent heat resistance. It is part of a family of superalloys that resist stress corrosion cracking and oxidation at temperatures up to 1300°F. Incoloy 803 also has high levels of ductility and strength when exposed to high temperatures. This makes it useful in many industries such as thermal processing equipment and chemical processing reactors. Additionally, because Incoloy 803 retains its strength at high temperatures, it can withstand higher pressures while maintaining its shape, making it ideal for many engineering applications where temperatures and pressures are too high for other materials.

Corrosion resistance:

Incoloy 803 is an alloy made of iron, nickel and chromium that offers exceptional corrosion resistance and excellent overall toughness, making it a very popular material in many industries. Its corrosion resistance comes from its unique composition, including high nickel, chromium, and molybdenum, which protects against a variety of corrosive environments. This corrosion resistance makes Incoloy 803 particularly attractive to job shops that may need this alloy to make parts exposed to potentially hazardous chemicals. Thanks to its properties, Incoloy 803 helps industries achieve safe and reliable environments with high performance despite harsh environments.

Processing:

Incoloy 803 should be machined using traditional methods such as turning, drilling or milling, but use the appropriate coolant or lubricant for best results. Other machining processes, such as grinding or EDM, should also be performed carefully following the manufacturer’s guidelines to extend tool life while maintaining surface finish quality.

welding:

Regarding welding, Incoloy 803 should be welded using TIG, MIG, SMAW and FCAW processes respectively, taking into account preheat temperature requirements, interpass temperature limits and post-weld heat treatment (if necessary).

in conclusion:

In summary, Incoloy 803 is an austenitic stainless steel alloy that offers superior corrosion resistance and high temperature capabilities compared to today’s alternatives while remaining cost-effective. Its unique composition allows it to be used in a variety of applications from food processing equipment to aircraft parts without sacrificing any performance metrics, whether you are welding, machining, or simply utilizing its excellent physical/mechanical/chemical properties! All in all, Incoloy 803 remains one of the favorite alloys among engineers around the world, so why not give it a try!

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Feb-21-2024