Hastelloy C2000:

Hastelloy C2000 is an austenitic nickel-chromium-molybdenum-tungsten alloy with excellent corrosion resistance in various corrosive media. It has good resistance to stress corrosion cracking and pitting corrosion and has excellent oxidation resistance compared to other alloys of similar composition. It also offers excellent formability and weldability, making it ideal for chemical processing equipment and heat exchanger applications.

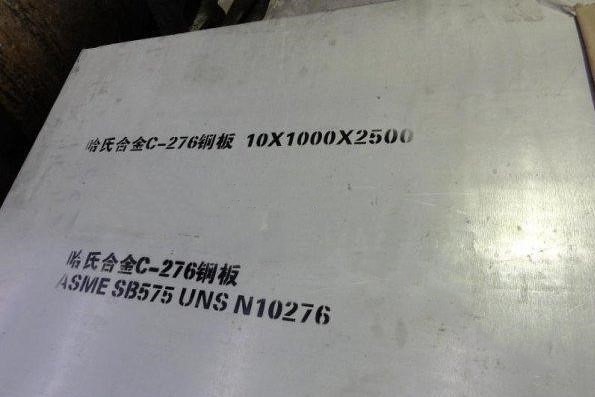

Hastelloy C276:

Hastelloy C276 is another nickel-chromium-molybdenum alloy that offers excellent corrosion resistance in both oxidizing and reducing environments. It has good weldability and formability and can be used in applications such as chemical process equipment and piping systems. However, it does not have the same tungsten content or antioxidant levels as Hastelloy C2000.

Hastelloy C276 vs. Hastelloy C2000:

Hastelloy C276 and Hastelloy C2000 both contain chromium, molybdenum, nickel, iron, manganese and silicon. However, Hastelloy C2000 also contains copper and tungsten.

Melting point:

The melting point of Hastelloy C276 is 1370 degrees Celsius, while the melting point of Hastelloy C2000 is 1425 degrees Celsius.

tensile strength:

Hastelloy C276 has a tensile strength of 655 MPa, while Hastelloy C2000 has a tensile strength of 724 MPa.

Yield Strength:

Hastelloy C276 has a yield strength of 413 MPa, while Hastelloy C2000 has a yield strength of 552 MPa.

Elongation at break:

Hastelloy C276 has an elongation at break of 30%, while Hastelloy C2000 has an elongation at break of 35%.

Elastic Modulus:

Hastelloy C276 has a modulus of elasticity of 193 GPa, while Hastelloy C2000 has a modulus of elasticity of 207 GPa.

in conclusion:

As you can see from the table above, both alloys offer excellent corrosion resistance, but have different compositions. Hastelloy C2000 has higher nickel and tungsten content than similar products while offering excellent oxidation resistance. Both alloys are highly weldable and formable, making them suitable for a variety of industrial applications that require high performance levels to handle harsh chemicals or extreme temperatures. Ultimately, which alloy you choose will depend on your specific needs; both offer excellent corrosion protection, but their properties may vary slightly depending on those needs. When selecting an alloy for your application, be sure to do your research to select one that meets your requirements!

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Jan-16-2024