Nimonic 101 is a high-performance nickel-based alloy popular in the aerospace, automotive and chemical industries. The alloy is known for its excellent mechanical and physical properties, such as high tensile strength and excellent resistance to corrosion and oxidation, making it suitable for use in extreme temperatures and harsh environments.

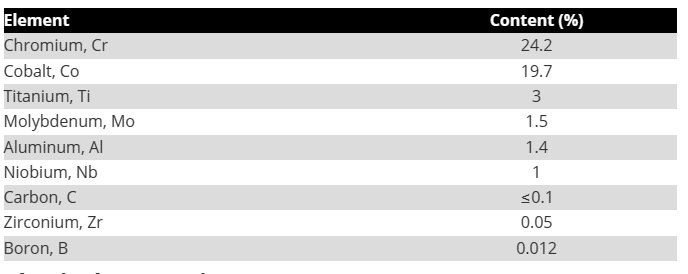

Nimonic 101 Chemical Composition:

Nimonic 101 is primarily composed of nickel, chromium and cobalt, with smaller amounts of titanium, aluminum and iron. In addition, it contains trace amounts of carbon, manganese, silicon, sulfur and phosphorus. This unique blend of ingredients enhances the alloy’s mechanical and physical properties, making it ideal for high stress and high temperature applications.

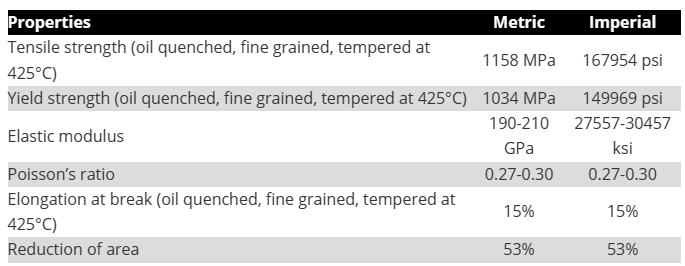

Nimonic 101 mechanical properties:

Nimonic 101 exhibits excellent tensile strength as well as creep and stress rupture resistance at elevated temperatures. Its room temperature yield strength is 525-710 MPa, and its ultimate tensile strength can reach 1030 MPa. In addition, the alloy has good ductility and impact strength, allowing it to withstand sudden shock and vibration loads.

Nimonic 101 uses:

Nimonic 101 is widely used in the aerospace industry for the manufacture of gas turbine blades, combustion chambers, exhaust nozzles and other high-temperature components. It is also used in chemical processing where resistance to harsh chemicals and acids is required. In addition, Nimonic 101 is used in automotive engines, power generation equipment and marine applications.

Nimonic 101 Corrosion Resistance:

Nimonic 101 has excellent resistance to oxidation, sulfidation and other forms of high temperature corrosion. The alloy’s chromium content forms a protective oxide layer on the surface, preventing corrosive agents from damaging the metal. This characteristic makes it suitable for use in environments exposed to corrosive gases, acids and high temperature water vapor.

Nimonic 101 heat treatment:

Nimonic 101 can be annealed at 1065°C for 8 hours and then slowly cooled to room temperature to improve its ductility and reduce residual stress. The alloy can be hardened and strengthened by solution treatment at 1080 to 1160°C, followed by rapid cooling in water or oil. The process enhances the mechanical properties of the alloy, making it suitable for high-stress applications.

Nimonic 101 Processing:

Nimonic 101 is difficult to machine due to its high strength and tendency to work harden. Therefore, the use of sharp cutting tools, low cutting speeds, and adequate cooling and lubrication are essential to obtain good surface finish and dimensional accuracy. Carbide and HSS tools are recommended for machining Nimonic 101.

Nimonic 101 Welding:

Nimonic 101 can be welded using conventional methods such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW) and resistance welding. However, alloys are susceptible to cracking during welding, requiring careful consideration of pre-/post-weld heat treatments, welding procedures, and filler materials. Therefore, it is recommended to consult a qualified welding expert before undertaking a welding project involving Nimonic 101.

in conclusion:

Nimonic 101 is a specialty alloy that offers exceptional strength, corrosion resistance and thermal stability. It is suitable for high temperature applications and harsh environments, making it the first choice for the aerospace, automotive and chemical industries. Understanding its ingredients, properties and processing methods is crucial to realizing its full potential and achieving success. So, whether you’re planning to use Nimonic 101 on your next project or are curious about its unique features, we hope this comprehensive guide provides valuable insight.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Mar-06-2024