UNS N05502 is a nickel-copper alloy that combines corrosion resistance with strength. It can be used in a variety of applications such as marine environments, chemical plants and heat exchangers. In this article, we will look at the composition of Monel 502, its chemical and mechanical properties, physical properties, uses, corrosion resistance, heat resistance, heat treatment processes, machining requirements and welding techniques.

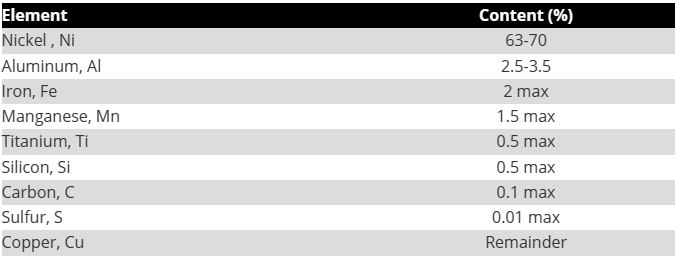

Monel 502 alloy chemical composition:

UNS N05502 is composed of 50% nickel and 47% copper with other trace elements including manganese (2%), iron (0.5%), silicon (0.3%) and carbon (0.1%). This combination of metals creates an alloy that is highly resistant to corrosion when exposed to salt water or other harsh chemicals. Additionally, due to its higher nickel content, the alloy retains its strength even at high temperatures.

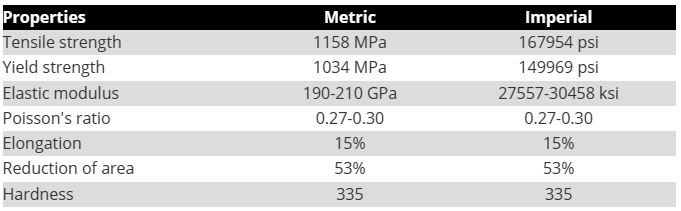

Monel 502 mechanical properties:

UNS N05502, due to its composition of nickel and copper, has excellent chemical and mechanical properties and is suitable for a variety of applications. The alloy has an ultimate tensile strength of 35 ksi (241 MPa) and excellent corrosion resistance in both acidic and alkaline environments. Additionally, it has good ductility and weldability, which makes it suitable for many different types of operations.

Monel alloy 502 uses:

UNS N05502 is popular because it offers many different uses, making it an ideal material for engineers looking for specific applications from material selection. It can be used in applications such as marine engineering due to its excellent corrosion resistance when exposed to salt water or other harsh chemicals in this environment; it can also be used in pressure vessels due to its ability to maintain strength even at high temperatures; and finally, It can be used in heat exchangers where its thermal conductivity helps transfer heat efficiently while maintaining structural integrity over time, even under extreme conditions such as inside boilers or furnaces that are exposed to high temperatures for long periods of time. will worsen. Time, the material itself shows no signs of failure or wear.

Corrosion resistance:

One of the key properties that makes Monel 502 so popular in many applications is its excellent corrosion resistance when exposed to salt water or other harsh chemicals in marine environments or industrial applications such as chemical plants.

Heat resistance:

Due to the presence of nickel, the alloy also has excellent heat resistance, retaining its strength even at extremely high temperatures, making it ideal for use inside boilers or furnaces where temperatures often exceed 3000°F (1649°C).

Heat treatment:

502 Monel alloy does not require any specialized heat treatment process before use, however, if desired, parts made from this alloy can be annealed after machining operations have been completed.

Processing requirements:

If possible, machining operations should generally use cutting tools with higher hardness grades (such as cobalt-based tools) rather than standard high-speed steel tools because they will last longer before needing to be replaced during production. When creating threads on parts made of this material, you should always use thread inserts rather than cutting the threads directly on the part itself, as doing so can cause excessive friction between the tools used in the production process. Permanent damage.

Welding Technology:

Special precautions must always be taken when welding parts made from metal alloys such as Alloy 502, as these alloys are not compatible with conventional welding techniques. Specialized filler materials should always be used when welding parts made of this type and certain preheating processes, depending on the joints being welded together. For example, butt joints need to be preheated to 400°F, while lap joints only need to be preheated to 300°F before welding begins. Additionally, special attention must be paid to shielding gas selection, as incorrect shielding gas can cause porosity issues during the welding process, leading to oxygen contamination within the weld pool, resulting in poor overall weld quality.

in conclusion:

Monel 502 is a very useful and versatile nickel-copper alloy that provides excellent mechanical strength and excellent corrosion protection, making it ideal for many industry applications including marine engineering pressure vessels, heat exchangers, automotive components and food processing industries. By understanding the chemistry behind this specific type of metal, engineers can choose the best option for their current project needs, knowing that the material they choose is reliable, durable, long-lasting, and won’t suffer degradation failures over time.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Mar-01-2024