Incoloy 945 is a nickel-iron-chromium alloy primarily used in applications where strength, corrosion resistance and heat resistance are critical. It has excellent mechanical properties and is easy to machine, weld and heat treat. This article will introduce all the properties and uses of Incoloy 945 so that you can better understand this alloy.

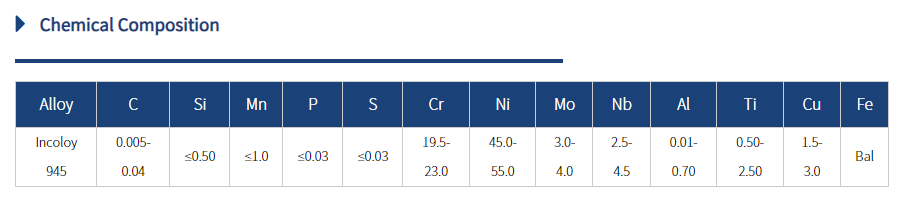

Incoloy 945 chemical composition:

UNS N09945 contains iron, nickel, chromium, molybdenum, titanium, copper and aluminum. Its chemical composition is as follows: Iron (Fe): 50%, Nickel (Ni): 28-33%, Chromium (Cr): 17-19%, Molybdenum (Mo): 3.7-4.3%, Titanium (Ti): 0.8- 1.2%, copper (Cu): 0.7-1.2%, aluminum (Al): 0.2%.

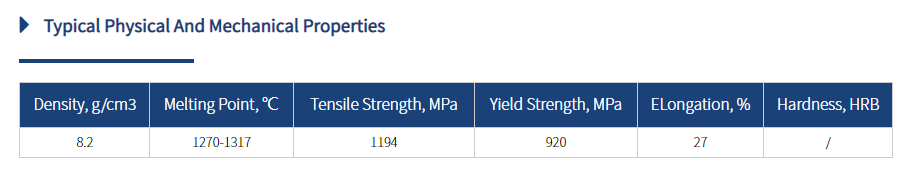

Incoloy 945 mechanical properties:

UNS N09945 has good mechanical properties at room and elevated temperatures due to its unique metallic composition, providing strength and durability even in extreme temperatures. The following are the mechanical properties of Incoloy 945 at room temperature:

Tensile strength – 830 MPa;

Yield strength – 690 MPa;

Elongation – 28%;

Hardness – 205 HBW;

Density – 7.89 g/cm3;

Modulus of elasticity – 200 GPa;

Poisson’s ratio – 0.3;

Shear modulus – 75 GPa.

These properties make it ideal for components requiring high strength and corrosion resistance at a wide range of temperatures, from cryogenic temperatures to high temperatures up to 1000°C.

Incoloy 945 uses:

Incoloy 945 is a specialty alloy designed for high temperature applications. It has excellent creep and stress rupture properties, making it ideal for applications in nuclear-powered trains and aerospace components that are subject to extreme temperature fluctuations over long periods of time. Its excellent wear resistance also makes it a commonly used metal in chemical processing equipment such as furnaces, evaporators, piping systems and reactors. Incoloy 945 is also becoming increasingly popular in the food industry due to its low toxicity and high heat resistance. This versatile metal alloy has a variety of uses, making it a valuable commodity in commercial and industrial settings.

Heat resistance:

Incoloy 945 alloy is a strong, heat-resistant alloy. It has excellent resistance to stress corrosion cracking, excellent resistance to oxidation and carburization even in high sulfur atmospheres, and good ductility at both high and low temperatures. This makes Incoloy 945 an ideal metal for extreme temperature applications in the aerospace industry, petrochemicals, utilities and industrial furnaces. With its advanced thermal properties, Incoloy 945 allows these industries to operate safely and efficiently in otherwise hazardous conditions.

Heat treatment:

Alloy 945 is a superalloy that undergoes a specific type of heat treatment to maximize its strength and corrosion resistance. Heat treatment involves heating the alloy to extremely high temperatures, allowing it to cool slowly under carefully controlled conditions, and then reheating the material at a specific temperature for varying lengths of time. This helps create the desired microstructure in the alloy and improves toughness and creep resistance. Additionally, because these processes also occur in an inert atmosphere, the uniformity and consistency of the heat treatment is improved, resulting in higher quality, longer-lasting Incoloy 945 parts.

welding:

UNS N09945 Welding is a specialized skill that requires precision and expertise to ensure good results. One of the main advantages of using Incoloy 945 is its excellent corrosion resistance, making it ideal for applications that require components with outstanding durability. Welders must be particularly careful when handling this material because it is more difficult to weld than stainless steel or other metal alloys due to its higher melting point.

Processing:

Incoloy 945 processing can be achieved with optimal efficiency. Careful use of milling cutters and drills ensures that materials are processed correctly to the highest standards. Skilled engineers are critical to the successful delivery of your Incoloy 945 machining project. They provide expertise throughout the entire process, and their knowledge of safety protocols ensures that all precautions are taken throughout the processing.

in conclusion:

In summary, Incoloy 945 is ideal for applications requiring high temperature strength as well as excellent corrosion resistance in harsh environments, such as chemical plants or refineries, as its unique composition gives it excellent mechanical properties as well as good thermal conductivity and low thermal conductivity Rate. The coefficient of friction makes it an ideal material for industrial components that must withstand extreme conditions while maintaining their performance over the long term without being subject to the damaging effects of chemicals or corrosion damage caused by acidic compounds commonly found in such factory environments. Making Incoloy 945 the perfect choice for many industrial applications that require excellent long-term performance under extreme conditions.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Feb-22-2024