Incoloy 330 is a specialized alloy known for its excellent high-temperature strength, resistance to oxidation and carburization, and exceptional corrosion resistance. It belongs to the family of austenitic nickel-iron-chromium alloys and is widely utilized in various industries that demand superior performance in extreme environments.

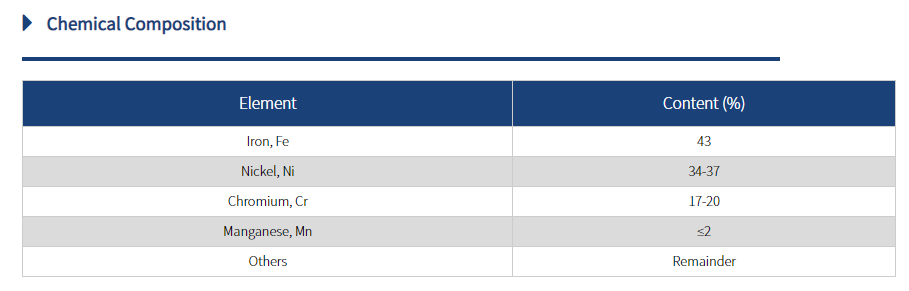

Composition and Properties: Incoloy 330, also known as Alloy 330, is composed of nickel, chromium, and iron as its primary elements. It typically contains around 34-37% nickel, 17-20% chromium, 1.5-2.5% silicon, and smaller amounts of manganese, carbon, sulfur, and copper. This unique composition imparts several key properties to Incoloy 330, making it highly suitable for high-temperature applications.

Incoloy 330 chemical composition:

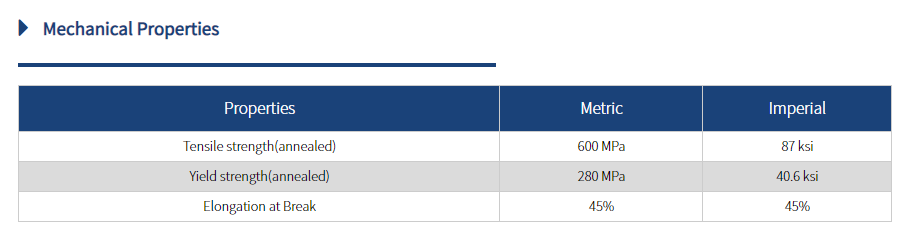

Incoloy 330 mechanical properties:

One of the standout characteristics of Incoloy 330 is its impressive resistance to oxidation and carburization at elevated temperatures. It forms a protective oxide layer on its surface when exposed to high heat, which helps prevent degradation and maintain its integrity over extended periods. This property is crucial for applications in furnace components, heat treatment equipment, and industrial heating systems where exposure to extreme heat is common.

Moreover, Incoloy 330 exhibits excellent corrosion resistance in a variety of environments, including aqueous solutions, acids, and alkalis. Its ability to withstand attack from chemical substances makes it a preferred choice for applications in the chemical processing, petrochemical, and power generation industries where exposure to corrosive media is a concern.

Applications of Incoloy 330: Due to its unique combination of properties, Incoloy 330 finds widespread use in numerous industrial applications. Here are some key areas where this alloy is commonly employed:

- Heat Treatment Equipment: Incoloy 330 is extensively used in the manufacturing of heat treatment furnaces, retorts, radiant tubes, and other high-temperature equipment. Its exceptional resistance to oxidation and carburization ensures long-term reliability and performance in these critical applications.

- Industrial Heating Systems: Incoloy 330 is a preferred material for heating elements, radiant heaters, and process heaters in industrial settings. Its high-temperature strength and resistance to thermal cycling make it ideal for withstanding the extreme conditions encountered in heating processes.

- Chemical Processing: Incoloy 330 is valued for its corrosion resistance in chemical processing environments. It is utilized in reactors, vessels, and piping systems where exposure to corrosive chemicals is prevalent, ensuring the longevity and integrity of critical equipment.

- Power Generation: In the power generation industry, Incoloy 330 is used in components such as boiler tubes, superheaters, and reheaters in fossil fuel-fired power plants. Its ability to withstand high temperatures and harsh operating conditions makes it an essential material for ensuring the efficiency and reliability of power generation systems.

- Aerospace and Automotive: Incoloy 330 is employed in exhaust systems, catalytic converters, and other high-temperature components in aerospace and automotive applications. Its heat-resistant properties and durability make it an ideal choice for parts that are subjected to extreme temperatures and environmental conditions.

Advantages of Incoloy 330: The use of Incoloy 330 offers several advantages for industrial applications:

- High-Temperature Strength: Incoloy 330 maintains its mechanical properties at elevated temperatures, providing reliable performance in demanding thermal environments.

- Excellent Oxidation Resistance: The alloy forms a protective oxide layer that protects against oxidation and ensures long-term durability in high-temperature applications.

- Superior Corrosion Resistance: Incoloy 330 exhibits resistance to a wide range of corrosive environments, enhancing the lifespan of equipment and reducing maintenance costs.

- Good Fabricability: Incoloy 330 can be readily fabricated and welded, allowing for the efficient manufacturing of complex components and assemblies.

- Versatile Applications: The alloy’s diverse range of properties makes it suitable for use in various industries, including aerospace, automotive, chemical processing, and power generation.

Conclusion: Incoloy 330 stands out as a high-performance alloy that offers exceptional strength, oxidation resistance, and corrosion resistance in high-temperature environments. Its superior properties make it a preferred choice for a wide range of industrial applications where reliability, durability, and performance are paramount. Whether in heat treatment equipment, chemical processing systems, or power generation plants, Incoloy 330 continues to demonstrate its versatility and value as a material of choice for challenging operating conditions.

As industries continue to push the boundaries of temperature and corrosion resistance requirements, the demand for advanced materials like Incoloy 330 is expected to grow. With ongoing research and development efforts focused on enhancing its properties and expanding its application range, Incoloy 330 remains at the forefront of innovative solutions for high-temperature challenges in the industrial sector.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Feb-22-2024