What is Alloy 48?

Alloy 48 is an iron-nickel alloy containing approximately 48% nickel that provides excellent ductility, corrosion resistance and strength properties. Its tensile strength can reach 800MPa and its elongation can reach about 60%. It also has excellent weldability, machinability and work hardening capabilities. Alloy 48 is used in various industrial applications due to its superior properties.

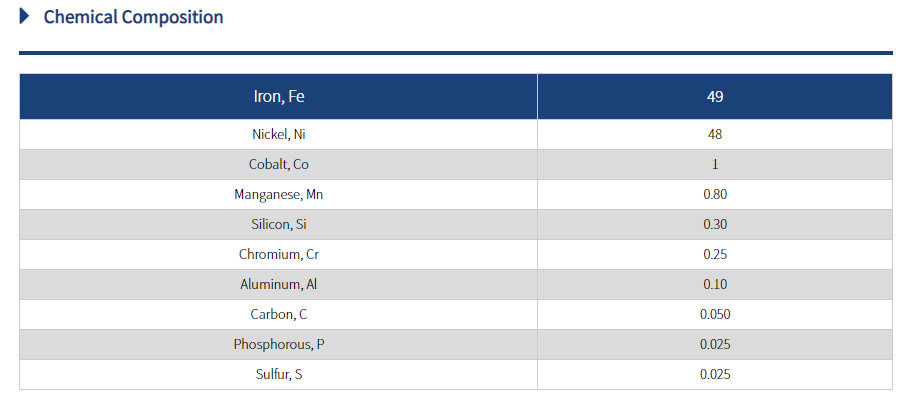

Alloy 48 Chemical Composition:

Alloy 48 contains nickel (48%), iron (51%), and small amounts of carbon, manganese, sulfur, and phosphorus. The large amount of nickel provides high thermal stability, while the iron provides low-temperature ductility.

Alloy 48 Mechanical Properties:

The mechanical properties of Alloy 48 make it a highly specialized alloy in the industry. Its tensile strength is between 586-725 MPa, and its yield strength is between 275-410 MPa. The alloy also has a high modulus of 167 GPa and is highly resistant to fatigue and stress cracking. Its high toughness and ductility also make it easy to cold and hot form.

▪ UNS K94800

▪ ASTM F30 Sheet, Strip, Rod, Bar, Tubing and Wire

▪ DIN 17745

▪ Werkstoff Nr.1.3922

▪ Werkstoff Nr. 1.3926

▪ Werkstoff Nr. 1.3927

▪ AFNOR NF A54-301

▪ Nilo Alloy 48

▪ SUPRA 50

Alloy 48 uses:

Alloy 48 is commonly used in the manufacture of electronic equipment such as transformers, inductors and other magnetic components. Its high magnetic permeability makes it ideal for applications requiring magnetic shielding, such as MRI machines. Alloy 48 is also used in precision instrument manufacturing, aerospace and defense industries.

Alloy 48 Corrosion Resistance:

Alloy 48 has excellent corrosion resistance in a variety of environments. Its high nickel content provides excellent resistance to sulfuric, hydrochloric and organic acid solutions. The alloy remains unaffected even by prolonged exposure to seawater, making it ideal for marine and offshore applications.

Alloy 48 Heat Treatment:

Alloy 48 can be heat treated to improve its mechanical properties. Solution annealing at 1050°C for 1 hour, followed by water quenching, will achieve maximum hardness and strength. However, the alloy can also be annealed at lower temperatures (750-1000°C) to improve its toughness and ductility.

Alloy 48 alloy processing:

Alloy 48 is relatively easy to machine, but requires high-speed tools and appropriate coolant to prevent work hardening. Tungsten carbide or diamond tools are also recommended for precision machining. The alloy can also be quickly joined by welding, soldering or soldering.

Alloy 48 welding:

Alloy 48 welding is a solid-state fusion welding process that uses an electric arc to join metals. The process requires high heat and produces strong welds with minimal distortion. It is often used when using other methods might be difficult or even impossible, such as those involving handling thicker and larger pieces of metal.

in conclusion:

Alloy 48 is a high-nickel-iron alloy with excellent mechanical and physical properties, making it highly regarded in the industry. Its high magnetic permeability, corrosion resistance and durability make it suitable for a variety of applications including precision instrument manufacturing, aerospace and defense industries. The alloy is relatively easy to work with and can be quickly joined by welding, soldering or soldering. Its superior performance makes it a reliable choice for applications requiring high strength, magnetic permeability and corrosion resistance.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Mar-06-2024